In 1573, the Italian monk St. Malalco made a doll-like mannequin out of wood and clay, and decorated it with scraps of rags. This is the early mannequin. Since then, mannequins were quickly introduced to France. A Parisian seamstress used this mannequin to show customers new clothes, and received unexpected results, which caused the tailoring world to follow suit. At the time, people called this mannequin dressed in fashion a "mannequin".

From this point of view, the production of early mannequins is very simple. The mannequins are now very beautiful. In the development and production, it has also achieved more advanced technology, which can meet the needs of more use.

So how do you make your own mannequin?

AFELLOW is one of the most influential mannequin developers, manufacturers and wholesalers.

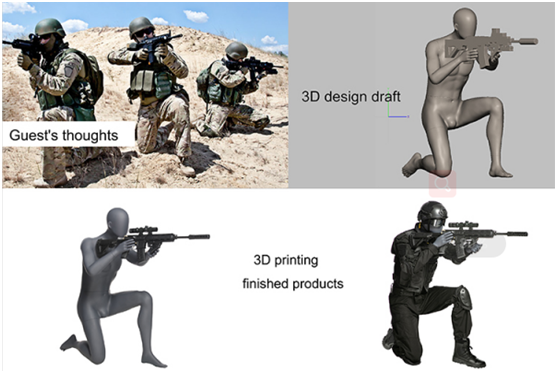

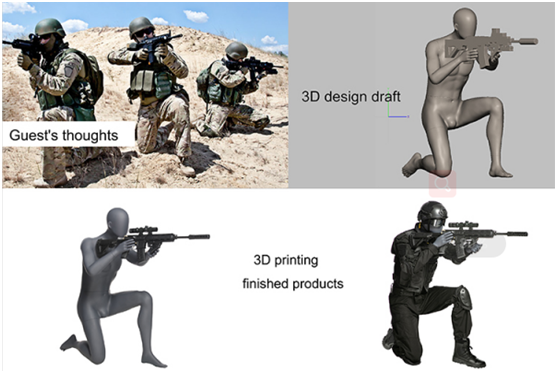

AFELLOW has its own professional design team and 3D printing center. If you want to customize one of your own mannequins, then you only need to provide pictures and your design requirements, AFELLOW can design for you according to your offer.

So how to see the sample? It was very easy, when the blueprints were finalized, they would cut the mannequins in the right places and put them in the 3D printing center to print the samples on the 3D printer. The samples are usually eco-friendly, recyclable and degradable PLA material. When you get the samples, you can see more clearly whether your customized products meet your requirements. After the samples are confirmed, the molds can be opened to produce large quantities of FRP materials.

This process is very easy for you, because you don't need to worry about any design and technical problems, AFELLOW will give you the most professional advice. Throughout the process you just have to make sure the design and whether the mannequins meet your requirements.

The mannequins are produced by traditional handcraft, and handwork is synonymous with texture and high-end. Using high-quality FRP raw materials, the model will be polished and trimmed at least three times after the model is taken out of the mold, so that the surface of the model is extremely smooth. Then enter the painting process, still use non-polluting and high-quality paint, and after three layers of primer and three topcoats, the mannequin enters the quality inspection process. As far as I know, many of our peers only do two coats of primer and two top coats. AFELLOW will spend more labor and material cost to make high quality products.

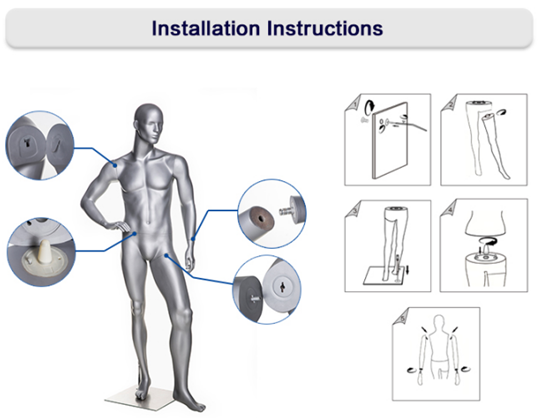

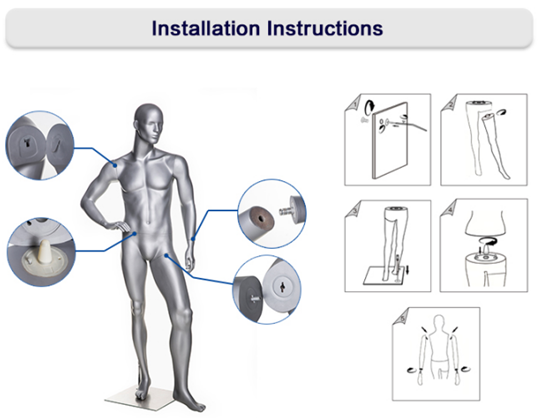

When it comes to the quality inspection, AFELLOW still does not relax the quality control. There are usually two quality inspection processes. They will check whether the surface of the mannequin is flawless, whether the overall proportion is deformed, and whether the connection keys are rusted. Of course, you can. Seeing that they use high-quality galvanized accessories, there will be no rust problems under normal circumstances. Defective products detected will be repaired or reworked in a timely manner. Each mannequin is carefully inspected before packing to ensure that the shipment is perfect.

The final step is packaging. They put a lot of thought into the way of packaging, so that good packaging can protect the mannequins from being damaged during transportation. They usually wrap each part of the mannequin's body with a thick bubble bag, and then put it into a 7-layer cardboard box, and fill the gaps in the carton with paper balls to ensure that the products inside the carton will not shake.

In short, AFELLOW is professional in mannequins, you only need trust and cooperate, and leave the rest to the AFELLOW team.